Hollow drill bit FHD

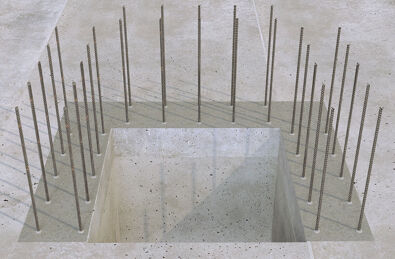

Hollow drill bit for drilling with low dust as well as for efficient and approved anchoring

In comparison to conventional hammer drill bits, the hollow drill bit enables a fast drilling progress due to the precision ground tips of carbide metal boards.

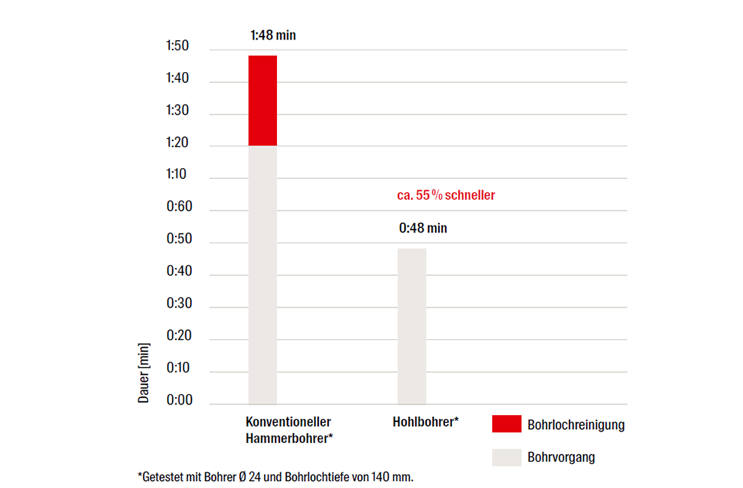

As illustrated in the graphic, additional time can be saved for the setting process since drill hole cleaning is no longer necessary.

In case of the hollow drill bit, the drill dust is evacuated directly at the drilling tip due to the vacuum drill system and the hollow cylindrical shaft.

Furthermore, costs for the cleaning equipment like cleaning brush, blow-out pump or compressed-air cleaning tool will be omitted.

*Tested with drill bit Ø 24 and drill hole depth of 140 mm.